Ford Flathead V8

FORD FLATHEAD V8 BACKGROUND

Ford had lead the automotive world, and society as a whole, since 1903. Ford applied modern production line techniques to building cars, the first to do so, and leapt ahead of everyone else in the industry. Over the next 19 years, Ford would produce some 17 million Model Ts, and literally put America on wheels. Their next major breakthrough would be the world’s first mass-market V8 engine. But making it affordable was the key, and the biggest challenge, as it meant the block would have to be cast in one piece, something that had never been done before. It took determination and many failed attempts to succeed, but succeed they did. Ford introduced their new 221 cubic inch flathead V8 in 1932, in a bargain-priced car. Until then, V8 engines were confined to expensive high-performance cars that most people had never even seen, let alone owned. Ford brought V8 power to the people, and the people rejoiced.

FORD FLATHEAD V8 DEVELOPMENT

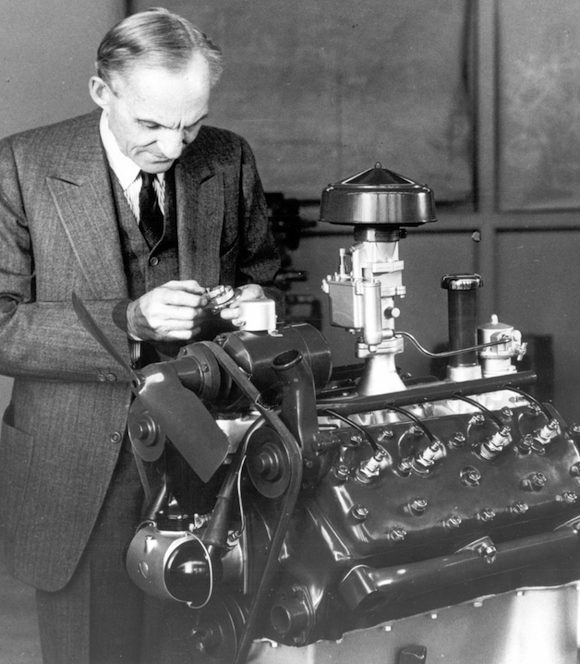

The Ford Flathead V8 was designed from a clean sheet, with Henry Ford himself at the helm of the project. The cylinders were arranged in a 90-degree V in a cast iron block with the crankshaft riding on just three main bearings. The cam rode above the crank in the crotch of the V, driving the intake and exhaust valves which were lined up along the inside of each cylinder bank. The intake tracks were fairly straight forward for a side-valve arrangement, fed by a central cast iron intake manifold and carburetor, mounted above the V on top of the engine. The head surfaces of the block were machined flat with cylinder bored and valve seats all lined up. The cast iron cylinder heads were incredibly simple affairs, one-piece with four combustion chambers, spark plug holes, bolt holes and a water jacket. No moving parts. The exhaust ports, however, passed between the cylinders, through the water jacket in the block, making their way to the outer sides of the engine, where they exited into the exhaust manifolds. A simple arrangement, but one that transferred enormous amounts of exhaust heat into the engine block and coolant. This forced Ford to oversize the cooling system on these relative small engines, much more so than on a comparable OHV engine.

FORD FLATHEAD V8 LEADS IN INNOVATION

While Ford’s extensive 4-cylinder engine experience was extensive, many things needed to be completely rethought and redesigned in the new V8. More power and the different configuration required new designs, materials and manufacturing techniques. The crankshaft, for instance, was originally forged steel, as was common practice at the time. But Ford pioneered the process of heat treating that allowed cheaper cast steel cranks to be manufactured that were just as strong as forged. While most V8s at the time were designed with the cylinder banks being bolted to a central crankcase, Ford innovated the casting of the block in one piece, called ‘monobloc design’. It made an affordable V8 possible. Early Flatheads used poured main bearings which required skill and a machine shop to accomplish, but replaceable main bearings were introduced in 1935. Lubrication was handled by a high-pressure oil pump, unlike many carmakers who chose “splash lubrication” as the simpler, cheaper route. Ford’s approach was much better. The left exhaust manifold exited to the front, with a cross-over pipe feeding into the front of the right exhaust manifold, which in turn exited at the rear. It was designed to be simple and durable, and it delivered a level of performance that had never been available to ‘normal people’ before.

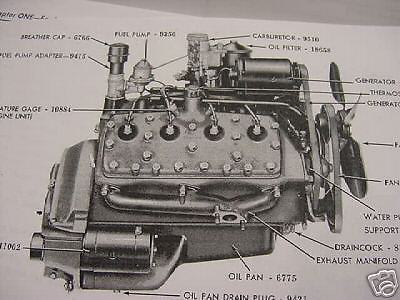

BELOW: The heart of the Ford Flathead V8, now you see why they also call flatheads “side-valves”, because the valves are alongside the cylinders. The entire head surface is machined smooth. The combustion chambers are in the heads, and spread over each piston and two valves. Low compression

FORD FLATHEAD V8s AS HOTRODS

Immediately after its introduction in 1932, the “Flatty” was the fastest engine that most normal people could afford. Naturally, the went right to making it faster. Ford Flathead V8s were so prolific at the time that a huge aftermarket parts industry sprang up to support these efforts. High compression heads, exhaust headers, multi-carb inake manifolds, wild cams and more all became widely available. Before World War 2, the Ford Flathead V8 was king. After the war, performance quickly ramped up from Ford’s competitors, and by the late 1940s and early 1950s, modern high-compression OHV V8s were being introduced by GM and Chrysler, and suddenly the venerable Flathead was hopelessly outclassed. Some still tried, well into the 60s, but even they very soon were relegated more to nostalgia hot rodding than the then-current high-performance landscape. But, today Ford Flathead V8s are making a huge comeback. After years of seeing ubiquitous Chevy Small Block in nearly every streetrod or custom, builders looking for something ‘different’ have rediscovered these wonderful old flathead V8 mills.

221 CUBIC INCHES / 3.6L, 1932-1942

The original Ford Flathead V8 had 221 cubic inches of displacement (known as the V8-18), with a 3.0635” X 3.75” bore and stroke. It was fed by a single 1-barrel carburetor, had a 5.5:1 compression ratio and made 65 horsepower when it was introduced in 1932. In 1933 Ford bumped the compression to 6.33:1 which was good for 75 hp (V8-40). In 1934, they added a 2-barrel downdraft carburetor, in 1935 they dropped the compression to 6.3:1 but still squeezed out 85 horsepower and 144 pound-feet of torque. In 1936 they changed the name to V8-68, but little else. Early 221s (1932-1936) had the water pumps mounted to the front of the heads, while 1937-and-later engines had the water pump mounted to the front of the block, and the water outlets moved from the front of the heads to the top-center of each head. These V8-78 engines were available with either aluminum heads with 6.2:1 and 85 hp, or optional cast iron heads with 7.5:1 and 94 horsepower. 1932-1938 Ford Flathead V8s have 21 head bolts on each cylinder head earning them the nickname “21 stud motors”. The V8-81A motor came out in late 1938 with 24 head bolts (“24 stud motor”). Subsequent variants were the V8-91A in 1939, the V8-01A in 1940, the V8-11A in 1941, and the last civilian version the V8-21A in 1942. It was used in some military vehicles during World War 2. 221 Ford Flathead V8s are called “85 horse motors”.

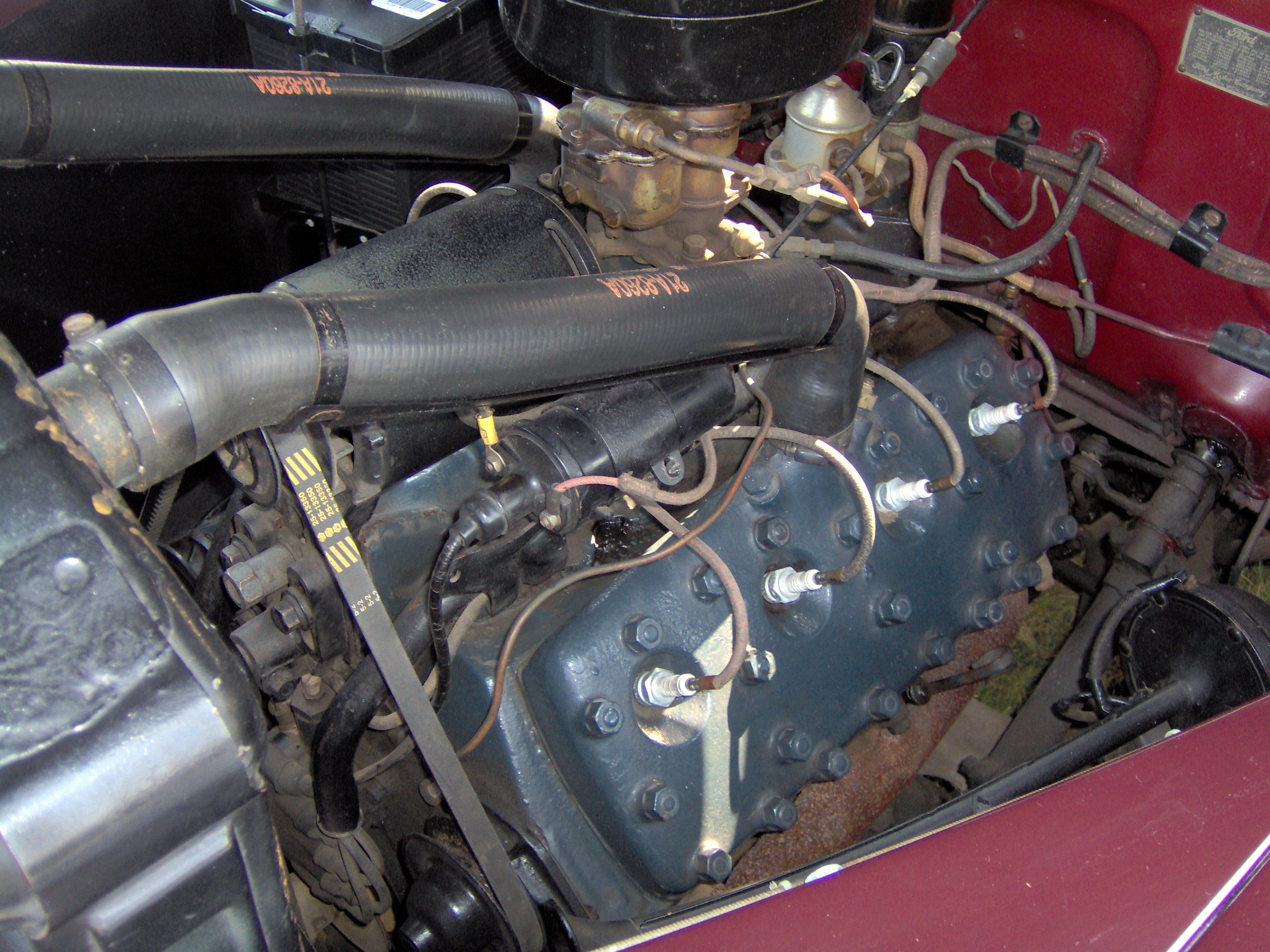

BELOW: This 221 Ford Flathead V8 shows how early engines were set up, with two water pumps, each mounted to the front of one of the heads.

239 CUBIC INCHES / 3.9L, 1939-1953

In 1939 Ford bored the 221 out to 3.1875” leaving the stroke alone at 3.75”, with a 6.15:1 compression ratio, giving the new 239 V8 (V8-09A) 95 hp and 170 lb/ft of torque. The 239 was used in Mercury passenger cars starting in 1939, but Ford buyers had to make do with the 221 until 1946. The 1941 V8-19A had the same power but made 176 lb/ft of torque, while the 1942 V8-29A got a compression bump to 6.4:1 and broke the 100-horsepower-mark. After the War, the 239 became known as V8-69. Compression and power rose incrementally over the years, to a peak of 7.2:1 and 110 hp respectively. The 239 Ford Flathead V8 remained in production until 1953 with it was replaced by Ford’s new OHV Y-Block V8. 239’s are commonly known as “100 horse motors”.

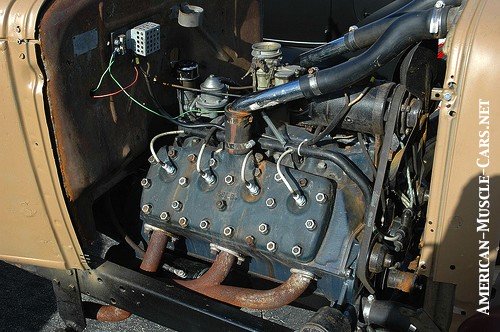

BELOW: This 239 Ford Flathead V8 shows how later engines were configured, still with two water pumps, but now they’re mounted to the front of the block, not the heads.

136 CUBIC INCHES / 2.2L, 1937-1941

This diminutive version of the Ford Flathead V8 had a 2.6” X 3.2” bore and stroke with a 6.6:1 compression ratio making 60 horsepower and 94 pound-feet of torque. This became Ford’s entry-level V8 of the era and was very popular with buyers. It was replaced in 1941 by Ford’s new 226 straight 6 engine.

255 CUBIC INCHES / 4.2L, 1948-1953

Ford stroked the 239 with a new 4.00”-stroke crankshaft to create the 255. It was considered a premium engine and as such was only used in Mercury passenger cars (not Fords) and heavy duty trucks. With a 6.8:1 compression it made 110 hp and 200 lb/ft of torque. A bump to 7.2:1 in 1952 brought 125 hp and 218 lb/ft. It remained in production until 1953, replaced in 1954 by Ford’s new family of Y-Block OHV V8s.

337 CUBIC INCHES / 5.5L, 1948-1951

The largest of all the Ford Flathead V8s, the 337 was designed for heavy truck use, but was adopted by Lincoln for their passenger cars in 1949. It was replaced in 1952 by the new OHV Lincoln 317 Y-Block.